A Complete Guide to Mould Manufacturing Services for OEMs and Startups

- Mefron Technologies

- Aug 4, 2025

- 3 min read

Updated: Aug 22, 2025

In product development, the transition from concept to tangible hardware depends heavily on precise tooling particularly moulds. Whether you're an established OEM or a startup entering the market, mould manufacturing services are critical in ensuring repeatable, scalable, and cost-effective production.

This guide covers the essentials of mould manufacturing, its relevance across industries, and how startups and OEMs can strategically leverage it for faster go-to-market and better product quality.

What Is Mould Manufacturing?

Mould manufacturing is the process of designing and producing moulds or tooling used in mass production processes like injection moulding, die casting, and compression moulding. These moulds define the shape, structure, and finish of the final component—be it a plastic casing, a metal housing, or precision parts used in consumer electronics, automotive systems, or medical devices.

Why Mould Manufacturing Matters

Consistency: Enables the production of identical components at scale.

Speed: Accelerates manufacturing cycles with automation-ready tools.

Precision: Supports complex geometries and tight tolerances.

Cost Efficiency: Reduces per-unit cost once tooling is established.

For OEMs, mould manufacturing supports high-volume production. For startups, it bridges the gap between prototype and product.

Key Steps in Mould Manufacturing

Design for Manufacturability (DFM)

Engineers evaluate the product design to ensure it can be efficiently moulded. DFM helps reduce material waste and avoid tool rework later.

Tool Design & Engineering

3D models and CAD simulations are used to design the mould based on production volume, material type, shrinkage rate, and cycle time.

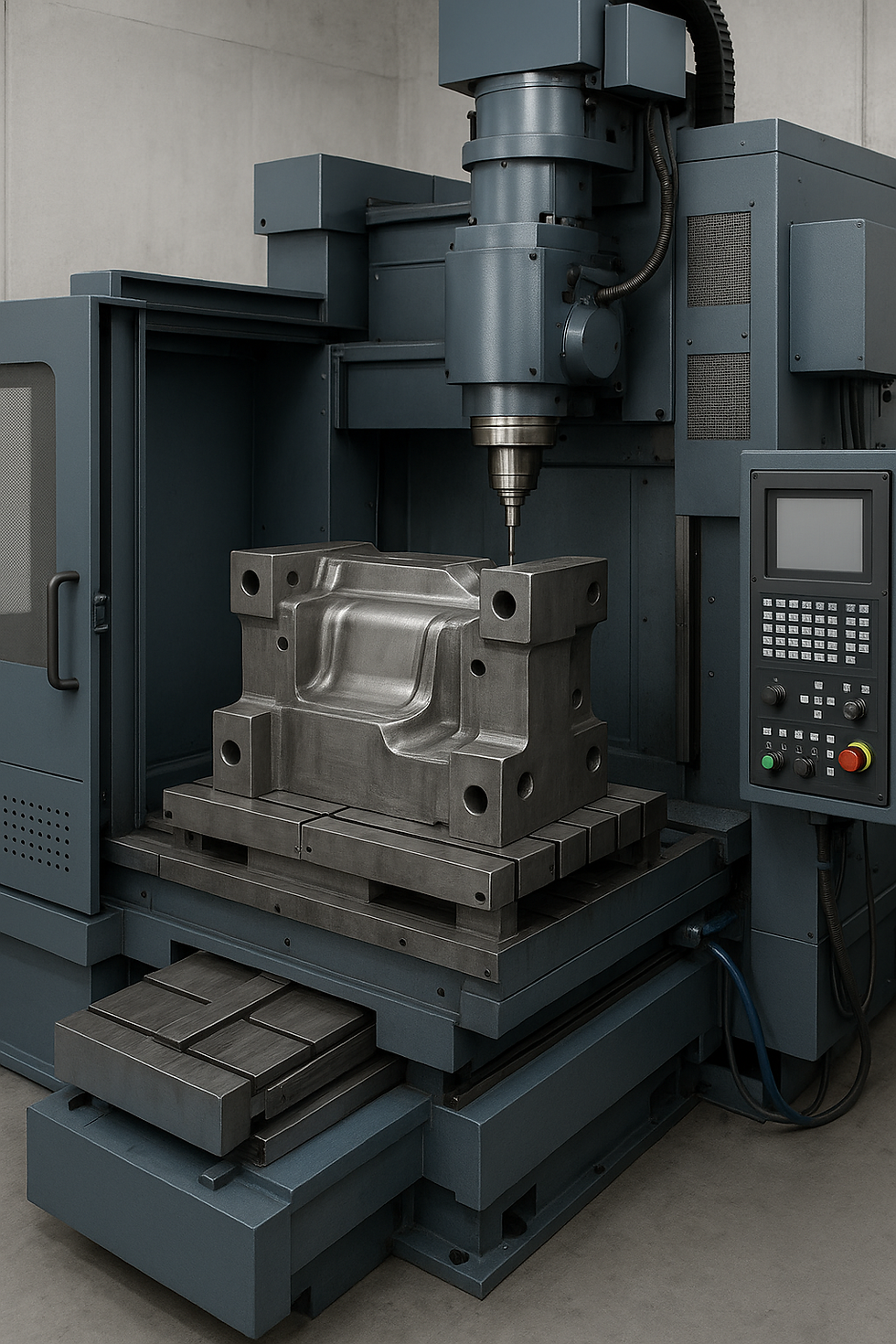

Tooling Fabrication

High-precision CNC machining, EDM (Electrical Discharge Machining), and grinding are used to create core and cavity inserts.

Assembly & Testing

The mould is assembled and tested through trial runs (T0, T1 samples) to detect issues like flash, warping, or dimensional inaccuracies.

Tool Validation & Optimization

Final adjustments are made to optimize part quality, production speed, and tool life.

Types of Moulds Commonly Used

Injection Moulds (for thermoplastics and elastomers)

Die Casting Moulds (for aluminium, zinc, magnesium)

Compression Moulds (used in rubber or thermoset plastics)

Multi-Cavity Moulds (produces multiple identical parts per cycle)

Prototype Moulds (low-cost, quick-to-deploy for limited runs)

When Should Startups Invest in Moulds?

Startups should consider mould manufacturing after validating the prototype and forecasting production volume. A few scenarios include:

Preparing for pre-series or pilot production

Entering into mass manufacturing agreements

Targeting industries where unit consistency is critical (e.g., medical, automotive, consumer electronics)

For startups, partnering with an EMS company that also offers mould development helps reduce lead times and streamline design iterations.

What OEMs Should Look for in a Mould Manufacturing Partner

In-house design and toolroom capabilities

Experience with your industry standards (e.g., ISO, IATF)

Support for revisions, maintenance, and tool repairs

Material and finish expertise (e.g., UV resistance, fire retardants)

Integrated services like plastic injection moulding or assembly

Benefits of End-to-End Mould Manufacturing with EMS Providers

OEMs and startups alike can benefit from integrated electronic manufacturing services that include tooling, moulding, assembly, and quality testing. It simplifies vendor coordination and ensures product designs are optimised for manufacturability right from the start.

For example, EMS companies that offer both Box Build Assembly Solutions and tooling capabilities can help reduce part incompatibility and assembly errors—leading to faster production ramp-up.

Final Thoughts

Mould manufacturing is not just a back-end process—it's a strategic enabler of reliable, high-volume product delivery. For OEMs, it ensures production efficiency; for startups, it unlocks the potential for scalable growth. By choosing the right partner and timing, you can transform a validated design into a commercial-ready product that meets market expectations.

If you're evaluating mould manufacturing services as part of your product journey, ensure your partner offers both technical expertise and flexibility to support you from early development to post-launch support.

Further Reading

If you find this blog interesting and want to read more such blog like this, then I would suggest please visit the Mefron blog page

Comments