How Tooling and Moulding Solutions Impact Product Lifecycle Costs

- Mefron Technologies

- Sep 6, 2025

- 2 min read

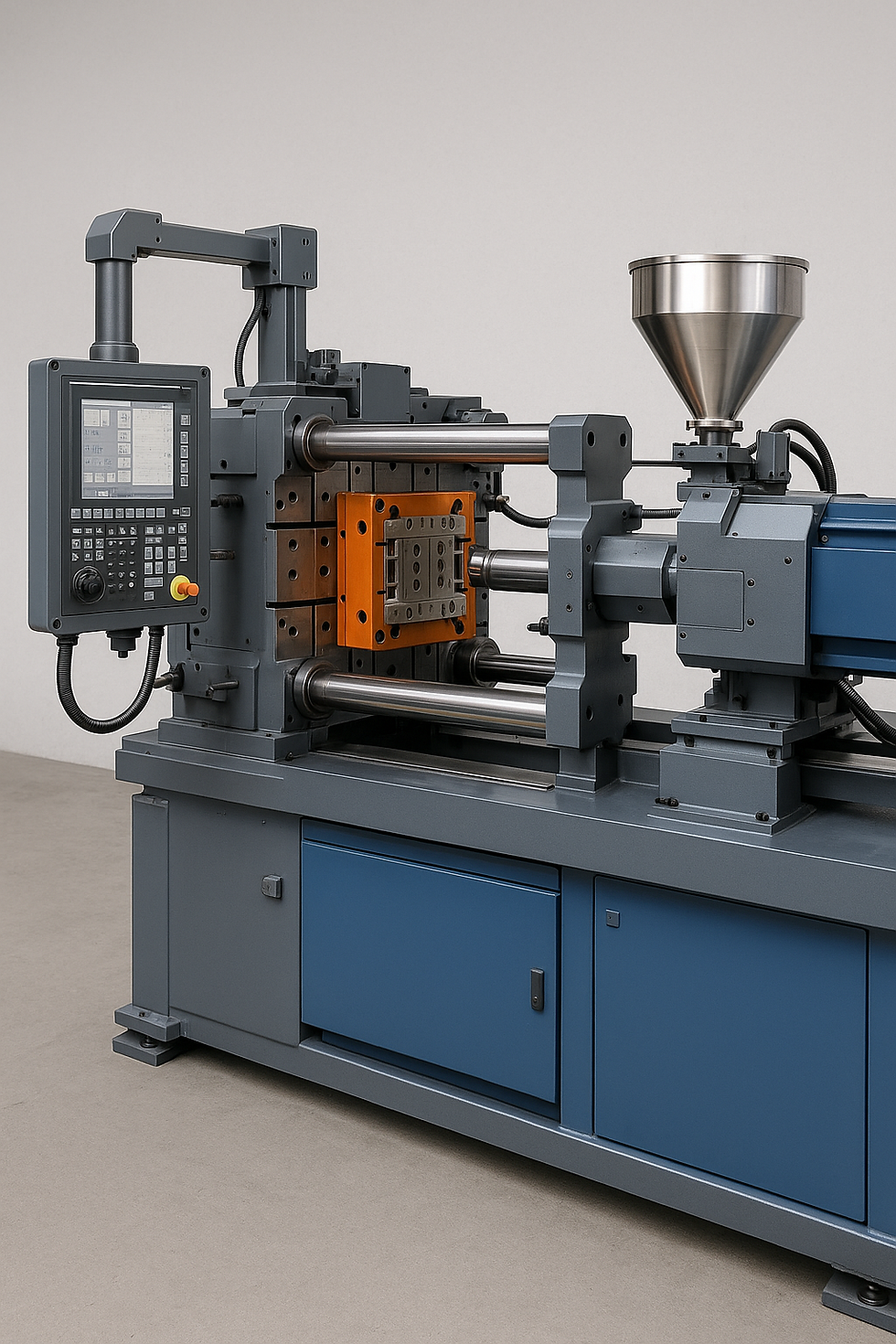

In manufacturing, every decision made during the design and production stages influences overall costs. Among these, tooling and moulding solutions play a critical role in determining the total expense across the entire product lifecycle. From initial prototyping to high-volume production and maintenance, the efficiency and quality of tooling directly affect cost, time, and product reliability.

1. Upfront Investment in Tooling

Tooling often accounts for a significant portion of the initial product development cost. High-quality moulds may require higher upfront investment, but they reduce long-term expenses by offering:

Greater durability and longer mould life

Reduced need for frequent repairs or replacements

Consistent part quality, minimising rework or scrap

While cheaper tooling may seem cost-effective at the beginning, it often leads to higher maintenance and quality-control expenses later.

2. Impact on Production Efficiency

Well-designed moulds improve cycle times, reduce material wastage, and support higher throughput. Faster and more efficient production not only saves operational costs but also ensures timely delivery to customers, which is crucial in competitive industries like automotive and consumer electronics.

3. Quality and Reliability of Parts

Precision tooling ensures uniformity and reduces defects in moulded components. Fewer defective parts mean less rework, fewer recalls, and lower warranty claims. Over time, this directly reduces the hidden costs that accumulate during a product’s lifecycle.

4. Flexibility and Scalability

Modern tooling solutions allow easy modifications and scalability. This flexibility helps manufacturers adapt to design updates or increased production demand without the need for entirely new moulds, lowering overall lifecycle costs.

5. Maintenance and Downtime Reduction

High-quality tooling and moulding systems are easier to maintain and less prone to breakdowns. Reduced downtime keeps production lines running smoothly, preventing revenue loss and additional repair costs.

6. Sustainability and Material Savings

Advanced moulding techniques can optimize material usage, minimize waste, and support sustainable manufacturing. By reducing raw material consumption, companies save costs while aligning with environmental compliance standards.

Conclusion

Tooling and moulding solutions are not just technical requirements; they are long-term cost drivers in the product lifecycle. Investing in precise, durable, and well-engineered moulds can significantly reduce expenses associated with production inefficiency, rework, downtime, and waste. In industries where margins are tight and product reliability is crucial, the right tooling strategy directly translates to lower lifecycle costs and stronger market competitiveness.

Comments